As architects and engineers become empowered to prescribe branded materials directly, building materials companies must reassess distribution. It may be wise to seek BIM-compatible manufacturers or invest in understanding software add-ons for optimal distribution strategies.

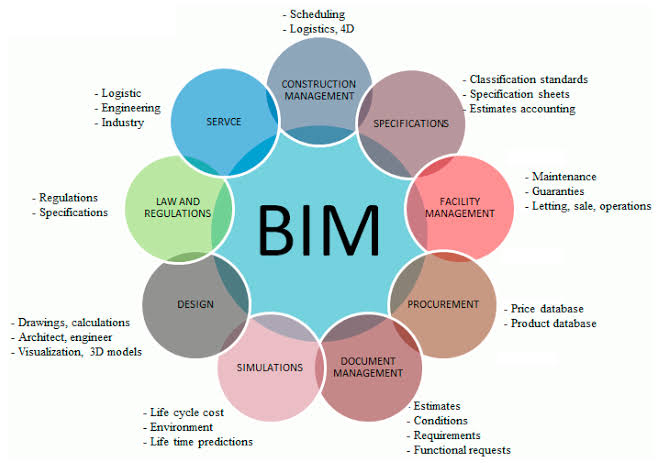

Building information modeling (BIM) allows for better visibility through computer models, providing clash detection to reduce site rework and communication breakdowns. Studies have shown that clash detection within a BIM model can reduce time spent handling errors on construction sites by as much as 90%.

1. Detailed Scheduling

Due to tight project timelines, multiple construction activities must often be conducted simultaneously at a construction site. To keep on schedule and prevent delays due to clashes in building construction. This necessitates meticulous attention paid towards finding and eliminating them as soon as possible.

Data-rich BIM modeling helps to alleviate such conflicts during planning phases by enabling stakeholders to collaborate more efficiently than before and coordinate at an improved and more accurate level than before. This makes fast-track scheduling feasible, shortening construction timelines.

BIM can store detailed information on how a construction method should be carried out, for instance how each element of a particular trade should be installed or how material storage space and accessibility should be managed.

This allows contractors to quickly create a fully-featured CPM schedule in seconds using this revolutionary 4D visualization, replacing traditional Gantt charts and providing real-time visual simulation of the construction process before even the foundation has been laid.

2. Just-in-Time Data-Driven Logistics

BIM projects allow all participants to collaborate on a shared digital model using compatible software, making the coordination between different disciplines and faster, clearer communication easier than ever before.

Coordinating deliveries to coincide with the building process allows material deliveries to arrive seamlessly, and provides an accurate record of materials used on-site – thus decreasing storage usage and unnecessary movement of material.

This method can be particularly effective for the delivery of moisture-sensitive goods such as windows and kitchens, which must remain protected. Furthermore, the over-ordering of materials is minimized.

Implementation and use of BIM systems often more than pay for themselves through cost savings during construction, with especially increased advantages being realized during projects that include planning or value analysis phases (Autodesk, 2017).

3. Factory-Assembled Modules

A unified BIM model gives all project participants access to information from a central source, which helps prevent information loss and reduce errors. Furthermore, having central access to comprehensive project data enables everyone to make better decisions more efficiently while decreasing costs.

Standardized building modules often necessitate large deliveries that need to be received as close to assembly points as possible, thus necessitating strategic logistics management. BIM can capture and share information about these modular parts as well as their relationships, providing invaluable coordination tools in the field.

Materials companies can hasten their transition to BIM by participating in policy working groups aimed at supporting government and industry decisions, helping shape their marketplace in their favor and avoiding being overtaken by competitors who have already moved into digital space.

4. Add-Ons

BIM models can provide invaluable information for facility management. Their highly detailed data makes renovation and maintenance much simpler, while the precise models help prevent human error or rework.

One of the primary risks in construction is errors, which can be costly. BIM helps mitigate human error by enabling collaboration teams to pre-check for clashes before entering sites. Clashes often result in wasted time and money and they’re even one of the leading causes of construction site fatalities!

Building materials companies looking to leverage the full value of BIM must quickly adapt their technologies. Doing so early could give them an early adopter edge and open up numerous new opportunities.

Light-side manufacturers could increase sales by offering features that highlight thermal or fire resistance, while heavy-side makers might create software tools to aid project managers manage material orders more effectively.

Ultimately BIM can assist the construction process in everything from designing to material management. Construction teams can greatly benefit from implementing BIM in their processes.

Read more…

How to Play Now.GG Roblox Games on your PC in 2023