Whether your epoxy has runny, cured too quickly, or stayed tacky for days, you can fix it by following these simple steps:

Uncured epoxy

If you are experiencing issues with your epoxy project, you should be able to solve these problems fairly easily. However, if the epoxy hasn’t cured properly, it can cause problems of its own. In order to avoid this problem, make sure that you are working in a well-ventilated area. In addition, you should wear protective gloves and a face mask while working with epoxy. Using an epoxy problem solver will help you find solutions to common problems.

In some cases, the temperature of the room and the Polymercaptan Resin can be the cause of the resin not curing properly. You should also be aware that a low temperature can prolong the cure time of the resin, but if it takes more than 48 hours, it isn’t likely to cure properly. Therefore, it’s better to wait until the time is right before you attempt to fix the problem. If the curing time is too short, you can try to prolong the curing time with the appropriate temperature or by leaving it out overnight.

To resolve the issue, you should mix the resin and hardener properly. A ratio of 1:1 is recommended for this. Mixing the two materials separately might cause the resin to separate from the hardener. If the mixture is not mixed properly, it will cause the resin to form a gooey mess. Fortunately, you can easily remove the excess resin by scraping it off and applying it anew. Just make sure to follow the instructions on the package, as measuring by volume may result in the incorrect amounts of hardener or resin. If the problem persists, you can simply add more hardener. But keep in mind that this will only make the resin cure slower.

Runny epoxy

If you’ve ever been tempted to skip the finishing process because you’re worried your epoxy resin won’t harden, you’ve most likely encountered the situation of a runny resin. While it is entirely possible that the resin simply didn’t cure properly, it is also possible to fix the problem. Here’s how to fix a runny epoxy resin so that you can get a shiny, glossy finish again.

The most basic way to fix runny epoxy is to clean it properly. To remove bubbles and to speed up the process, try applying a coat of paint thinner. If the bubbles are too large to be removed, try a pinch of talcum powder. A heating pad or hairdryer can gently warm the epoxy, but use caution: too much heat can cause the resin to yellow or lose its gloss. A UV light can also speed up the process, but you must use a UV-resistant clear coat.

One of the most common causes of runny epoxy resin is a mismeasured amount of hardener or resin. Mix the two components of epoxy resin exactly by volume, and if the resin remains wet after curing, scrape off the excess and apply fresh. Then, wait for the new resin to cure. If it takes a while, the uncured resin might not have fully hardened yet.

Tacky epoxy

One of the main causes of runny Epoxy Curing Agent is deviating from the manufacturer’s instructions. To fix this problem, you’ll need to clean the workpiece thoroughly and remove any residual epoxy that may be present. Some runny epoxy will remain clogged in corners and grooves. You should then mix a fresh batch of epoxy, making sure to use the correct ratio. This will ensure that your piece will be smooth and perfectly cured.

A sticky epoxy surface is an indication that the resin didn’t cure properly. It’s a common occurrence that occurs when improperly measuring resin and hardener or improper mixing. To fix it, scrape off the uncured epoxy, sand the surface, and apply a fresh layer. Afterwards, repeat the process until the original layer has fully cured. Ideally, the first coat of epoxy should cure completely.

Conclusion

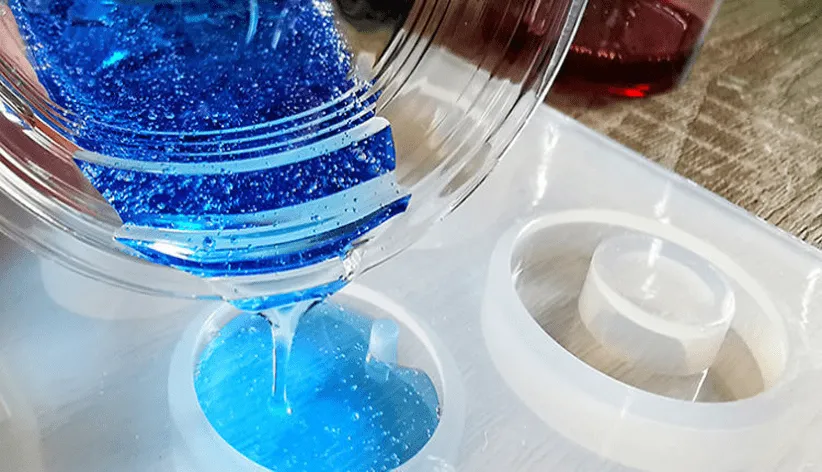

If you have dropped some epoxy on your work, you can scrape it off with a spoon or a piece of cardboard. After scraping off any excess epoxy, pour the resin into a separate container. Use a stir stick to mix the material thoroughly. Using a timer, keep track of the time and scrape the sides of the container to ensure complete mixing. In addition, the epoxy should be at room temperature when mixed.